Due to the rapid overall development of China's economy, baby diapers have become an essential baby product for many young mothers. However, for those who are not familiar with the production process of baby diapers, it remains a mysterious topic. How can such a thin product absorb a large amount of urine from a baby? What are the mysterious materials used to bond the various layers of a diaper together? With these questions in mind, let us explore some of the important basic raw materials used in baby diapers.

Core Material Section

Currently, there are two popular types of absorbent cores used in baby diapers on the market. The first type is the conventional absorbent core, which is a mixture of wood pulp and superabsorbent polymer (SAP) materials in a certain proportion. The wood pulp fibers guide the urine into the absorbent core, and the superabsorbent polymer, also known as absorbent powder (beads), locks in the urine with its strong water retention properties, ensuring that the surface of the diaper remains dry even after absorbing a substantial amount of urine. However, due to the presence of wood pulp, issues like clumping and layering are inevitable.

The second type is the ultra-thin absorbent core, which is a blend of dust-free paper, fluffy non-woven fabric, and superabsorbent polymer in a specific proportion. This new type of core guides urine through the dust-free paper to the superabsorbent polymer, and a layer of fluffy non-woven fabric secures the polymer in place. Therefore, regardless of how much urine the superabsorbent polymer absorbs, it is fixed in the center of the core, making it less prone to clumping and layering compared to the conventional core.

From the above descriptions, it is evident that both types of absorbent cores rely on an essential material: superabsorbent polymer (SAP). This material is the key to why a thin diaper can absorb a large amount of urine.

Hot Melt Adhesive Section

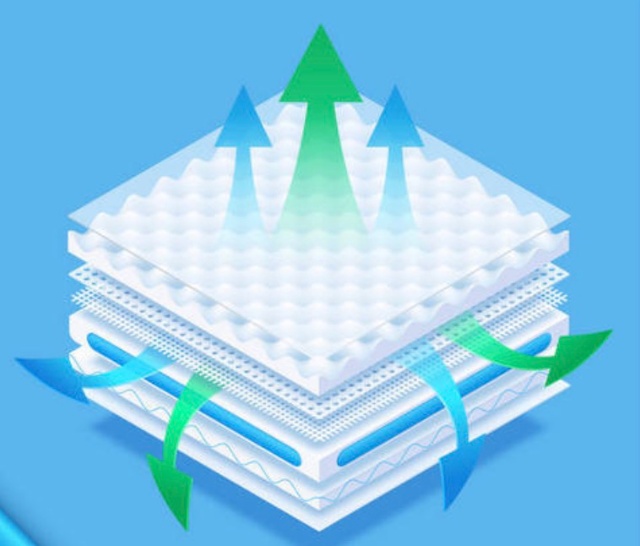

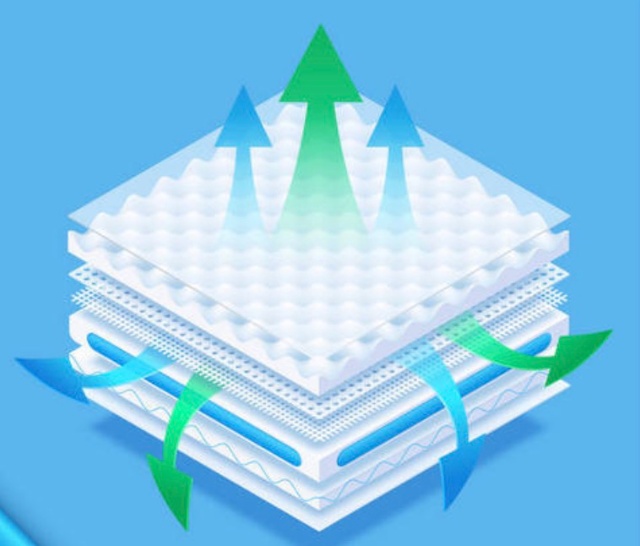

In fact, the production process of diapers is quite complex. Diapers are made of numerous raw materials, including surface non-woven fabric, leak-proof side non-woven fabric, absorbent core, core-wrapped non-woven fabric, backsheet, backsheet non-woven fabric, frontal tape, side tapes, waistband non-woven fabric, and elastics. These materials are laminated together on a fully automated production line using precise amounts of hot melt adhesive.

Non-Woven Fabric Section

It is composed of oriented or random fibers and is a new generation of environmentally friendly materials. A few years ago, most diaper brands, whether international or domestic, predominantly used spunbond non-woven fabric. However, as young mothers' requirements for diapers have increased, ranging from functionality to softness and skin-friendliness, the industry has introduced high-end products using hot air non-woven fabric for the backsheet non-woven layer.