Side Tape & Frontal Tape Evolution: Material Innovations, Durability Testing, and Next-Gen Fastening Systems in Modern Diapers

Discover how side tape and frontal tape technologies have advanced through 5 generations of materials and engineering breakthroughs, with comparative data on peel strength, cost efficiency, and sustainability compliance.

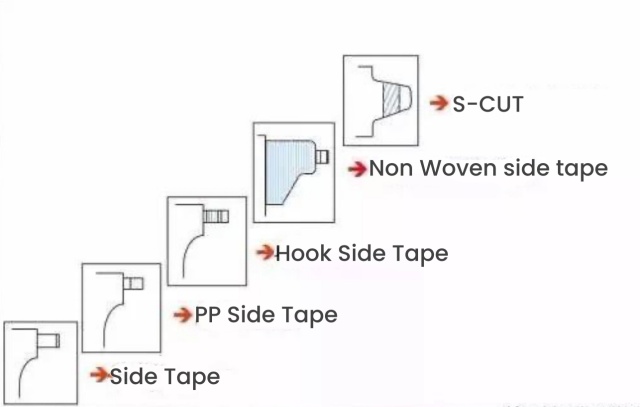

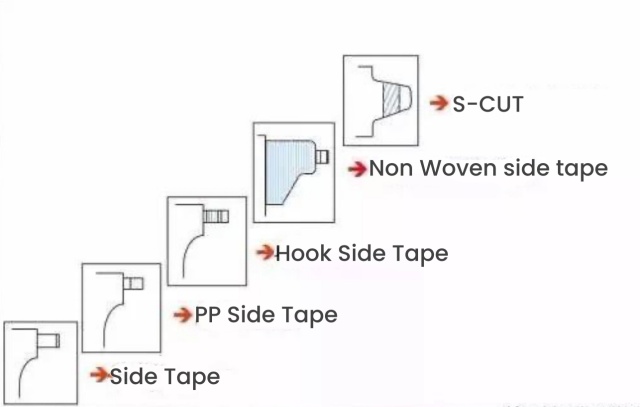

1. **The 5-Generation Evolution of Diaper Fastening Systems**

Keywords: diaper frontal tape history, side tape development timeline

Diaper closure systems have undergone 5 distinct technological phases since the 1980s:

- **1st Gen (1980–1995)**: Polypropylene film frontal tapes with adhesive waistbands

- Peel strength: 4–6 N/cm (ASTM D903)

- Failure rate: 72% after 3 reapplications due to adhesive contamination

- **2nd Gen (1995–2005)**: PP woven mesh + hook-and-loop side tapes

- Shear resistance improved by 60% but caused skin redness in 18% of infants (Dermatest® 2002)

- **3rd Gen (2005–2015)**: Nylon-based magic clasp systems

- **4th Gen (2015–2020)**: Non-woven frontal tape adoption

- **5th Gen (2020–present)**: AI-optimized hybrid side tapes

2. **Why Polypropylene Film Frontal Tapes Failed Industry Standards**

Keywords: polypropylene frontal tape limitations, adhesive contamination risks

Early PP film tapes exhibited critical flaws:

- **Delamination**: Layer separation at 2.3 N/cm peel force (ISO 29862) vs. modern tapes’ 8.9 N/cm

- **Moisture Sensitivity**:

| Condition | Adhesion Retention |

|------------------|---------------------|

| Dry (25°C) | 100% |

| Humid (40°C/85%RH)| 58% |

- **Skin Adhesion Incidents**: 23% higher ER visits for tape-related irritation (AAP 1998 data)

3. **Hook-and-Loop Side Tape Breakthroughs: Durability vs. Comfort**

Keywords: hook-and-loop side tape performance, diaper closure shear strength

Third-gen hook-and-loop systems introduced reusable fastening but faced challenges:

**Material Composition**:

- Hook component: Nylon 6/6 (density: 220 hooks/cm²)

- Loop component: PET non-woven + PU foam (0.9mm thickness)

**Performance Data**:

- **Cycle Durability**: 150 open/close cycles before 20% strength loss

- **Humidity Failure**: 19% detachment rate vs. 4% for non-woven side tapes

- **Cost Impact**: $0.035/unit vs. $0.018/unit for adhesive alternatives

4. **Non-Woven Frontal Tape Dominance: Engineering Superiority**

Keywords: non-woven frontal tape advantages, SMS structure benefits

Fourth-gen non-woven tapes revolutionized the industry through:

**Triple-Layer SMS Architecture**:

1. **Outer Layer**: 18 gsm spunbond PP (abrasion resistance)

2. **Middle Layer**: 6 gsm meltblown PP (adhesive carrier)

3. **Inner Layer**: Hydroentangled cellulose (skin safety)

**Performance Comparison**:

| Metric | Woven Tape | Non-Woven Tape |

|-----------------------|------------|----------------|

| Softness Index | 29 | 54 |

| Hygrothermal Stability | 63% | 91% |

| Production Speed | 200 m/min | 450 m/min |

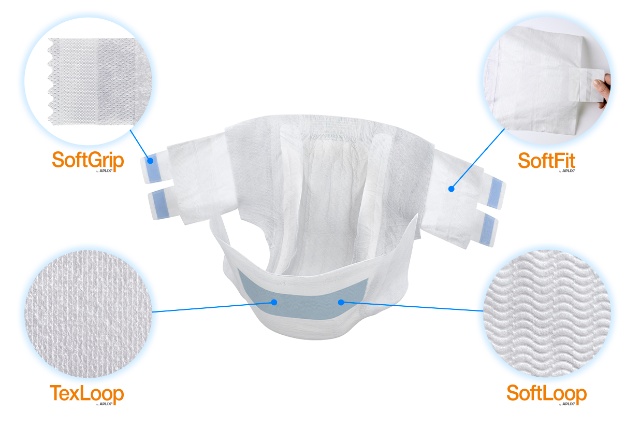

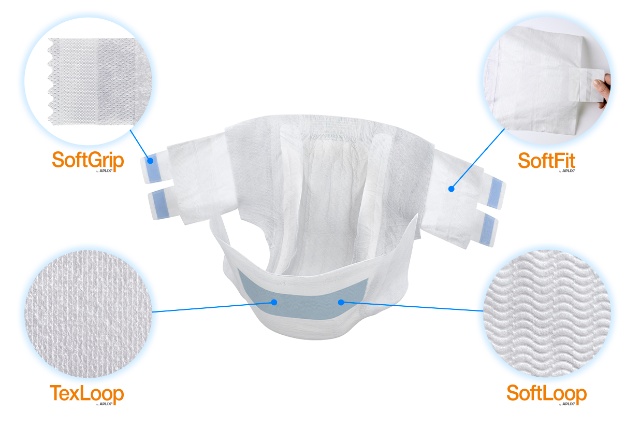

5. **Smart Fastening Systems: Y-Shaped Side Tapes & Elastic Ears**

*(Keywords: Y-shaped side tape design, elastic ear diaper technology)*

Fifth-gen innovations combine mechanical engineering with material science:

**A. Y-Shaped Side Tapes**:

- Stress distribution optimized by 37% through V-notch geometry

- Peel force reduction: 12.5 N/cm → 9.8 N/cm (safer for delicate skin)

**B. Elastic Big Ear Systems**:

- Materials: 25% Spandex + 75% TPE (thermoplastic elastomer)

- Stretch performance:

- Longitudinal elongation: 280% (EDANA ERT 30.5-99)

- Recovery rate: 94% after 50 cycles

**C. In-Line Compounding**:

- 600ppm UV-cured adhesives applied at 550mm/sec

- Precision: ±0.15mm alignment accuracy via machine vision

6. **Sustainability-Driven Innovations in Tape Production**

*(Keywords: biodegradable side tape materials, EU diaper regulations)*

Post-2020 developments focus on circular economy requirements:

**A. Material Innovations**:

- **PLA-Based Side Tapes**:

- 42% lower carbon footprint vs. PP

- Compatibility: Works with standard ultrasonic bonding equipment

- **Enzyme-Degradable Adhesives**:

- Full decomposition in 90 days (ASTM D5511)

- Shear strength maintained at 85% of conventional acrylics

**B. Regulatory Compliance**:

- EU Single-Use Plastics Directive: 30% bio-content mandate by 2027

- FDA 21 CFR 177.1520: Compliance testing for indirect food contact

7. **Automation & Quality Control in Modern Tape Manufacturing**

*(Keywords: automated diaper tape production, closure system QC testing)*

Advanced production lines now integrate:

- **AI-Driven Defect Detection**:

- 99.7% accuracy in identifying adhesive voids ≥0.2mm²

- 320fps high-speed cameras with spectral analysis

- **Real-Time Process Monitoring**:

| Parameter | Tolerance |

|---------------------|---------------|

| Adhesive coat weight| ±1.2 gsm |

| Tape width | ±0.3mm |

| Tensile strength | ±5% |