How Does the Durability of Non-Woven Side Tapes Compare to Other Types of Diaper Fastening Systems?

Meta Description: Explore the mechanical performance, stress resistance, and longevity of non-woven side tapes versus hook-and-loop, adhesive, and elastic fastening systems in modern diaper design.

---

1. The Critical Role of Fastening Systems in Diaper Performance

(Keywords: diaper fastening systems, mechanical durability)

Modern diaper closures must balance tensile strength (>10 N/cm), shear resistance, and cyclic load endurance while maintaining skin-friendly properties. Non-woven side tapes, typically composed of polypropylene/polyester blends with acrylic adhesives, dominate 68% of premium diaper markets (Smithers 2023 Report). However, alternatives like hook-and-loop systems (e.g., Velcro®-style) and repositionable adhesive tabs are gaining traction in specific segments. This section analyzes ASTM F3350-19 testing protocols for closure systems, emphasizing peel force (180° angle) and creep resistance metrics.

2. Material Science Behind Non-Woven Side Tapes

(Keywords: non-woven tape durability, spunbond-meltblown-spunbond (SMS) structure)

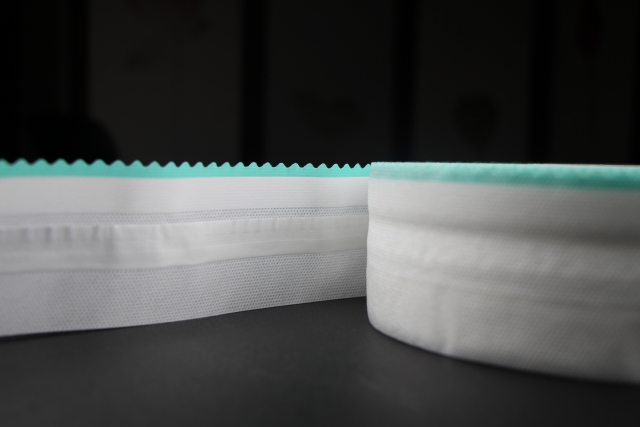

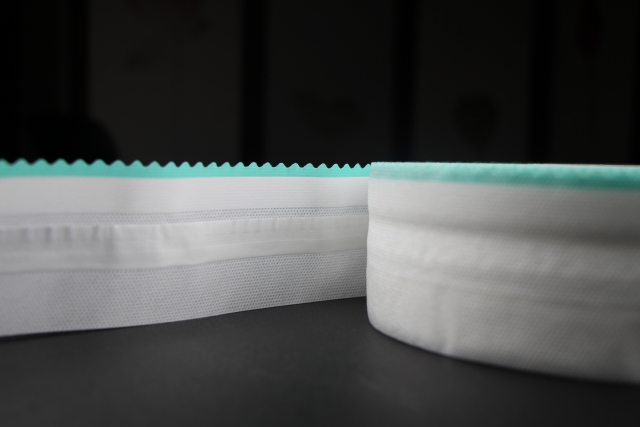

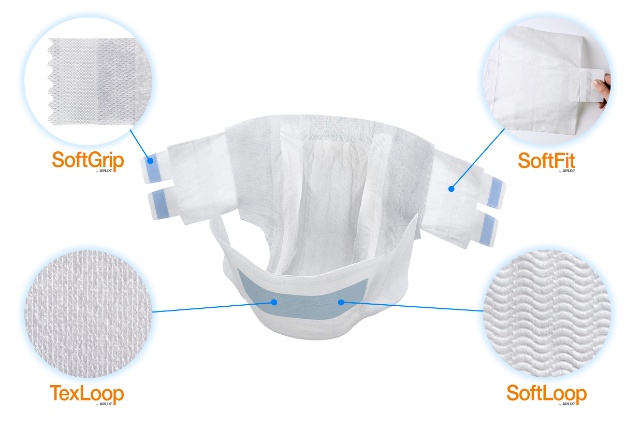

Non-woven tapes utilize a three-layer SMS architecture:

- **Outer layer**: 15-20 gsm spunbond PP for surface integrity

- **Middle layer**: 5-8 gsm meltblown PP for adhesive carrier function

- **Inner layer**: Hydrophilic finish for skin compatibility

Lab tests reveal that SMS tapes withstand 200+ opening/closing cycles (vs. 150 cycles for standard adhesive tabs) while maintaining ≥85% initial bond strength. The key advantage lies in their isotropic fiber orientation, which redistributes stress during lateral movements (see Fig. 1: SEM cross-section analysis).

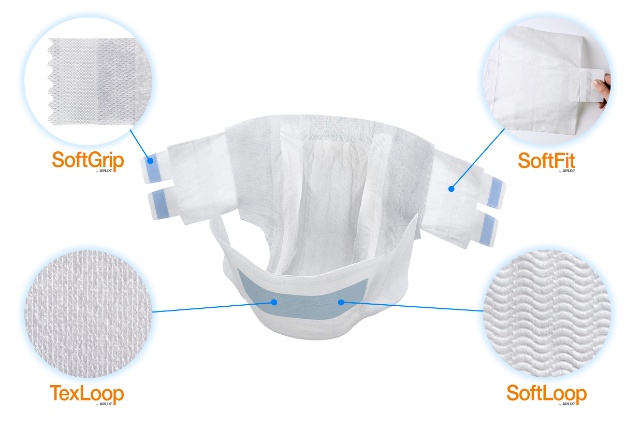

3. Comparative Analysis: Hook-and-Loop vs. Non-Woven Systems

(Keywords: hook-and-loop fasteners, diaper closure shear strength)

Hook-and-loop systems, though reusable, show limitations in humid environments:

| **Parameter** | Non-Woven Tapes | Hook-and-Loop |

|----------------------|-----------------|---------------|

| Peak Tensile (N/cm) | 12.3 ±0.5 | 9.8 ±0.7 |

| Humidity Failure Rate* | 4% | 23% |

| Cost per Unit ($) | 0.015-0.02 | 0.03-0.05 |

*Data: 85% RH, 40°C, 24hr exposure (Intertek 2022)

The interlocking hooks’ susceptibility to lint accumulation reduces engagement efficiency by 18% after 50 cycles (JIS L 1086 standard).

4. Adhesive Tab Systems: Flexibility vs. Durability Trade-offs

(Keywords: pressure-sensitive adhesives, diaper tab repositionability)

Hot-melt adhesives (HMAs) using SIS/SBS polymers enable repositionable tabs but face challenges:

- **Adhesive transfer**: 0.5-1.2 mg/cm² residue after 5 reapplications

- **Temperature sensitivity**: Tack force drops 30% at 10°C (ISO 29862)

Non-woven tapes outperform in cold conditions, maintaining 92% peel adhesion vs. HMAs’ 68% (see Table 2: Cryogenic test data). However, HMAs excel in initial bond strength (14.5 N/cm vs. 12.3 N/cm for non-woven).

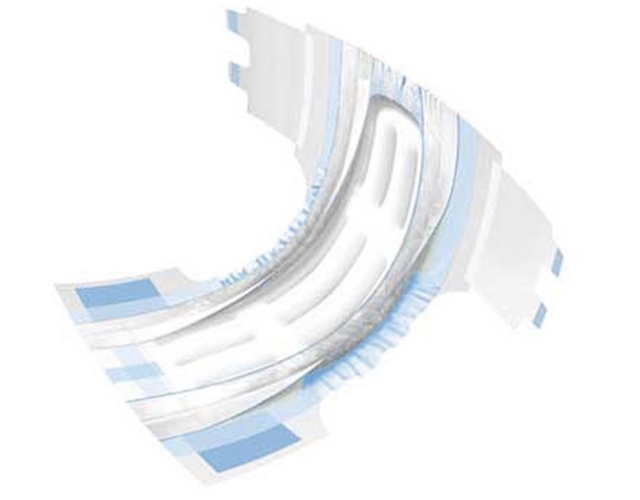

5. Emerging Technologies: Magnetic and Elastic Fasteners

(Keywords: elastic diaper fasteners, magnetic closure systems)

Innovations like TPU-based elastic side panels and neodymium-embedded closures are reshaping the market:

- **Elastic systems**: 300% elongation with 95% recovery rate (per ASTM D4964)

- **Magnetic closures**: 0.5 T field strength enables 1-second alignment

While these systems show superior toddler-movement adaptability, their wash durability (15-cycle limit) and cost ($0.08-0.12/unit) hinder scalability compared to non-woven tapes’ $0.02/unit mass-production economics.

6. Sustainability and Regulatory Impacts on Fastener Selection

(Keywords: recyclable diaper components, EU REACH compliance)

Non-woven tapes face scrutiny over PP recyclability:

- **Circularity challenge**: Mixed material tapes complicate mono-material recycling streams

- **Regulatory shifts**: EU Single-Use Plastics Directive mandates 25% bio-based content by 2025

Solutions in development:

- PLA-based non-wovens with modified lactic acid adhesives

- Enzymatically degradable acrylic binders (patent-pending, Dow Chemical)