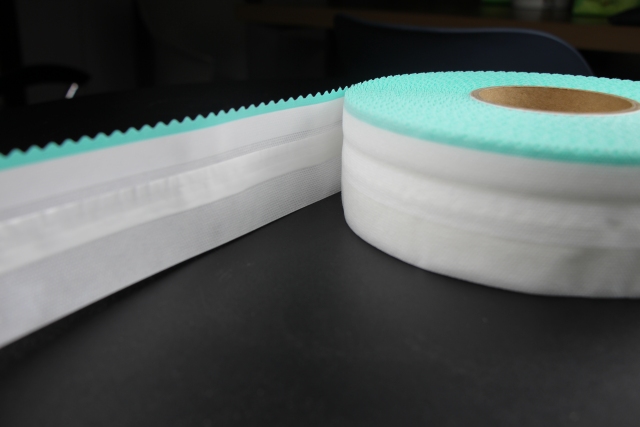

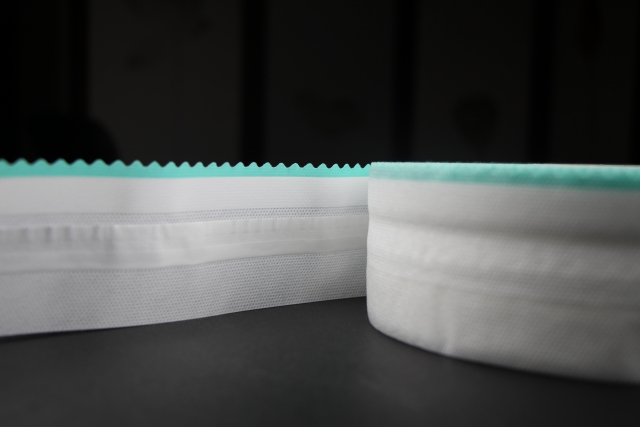

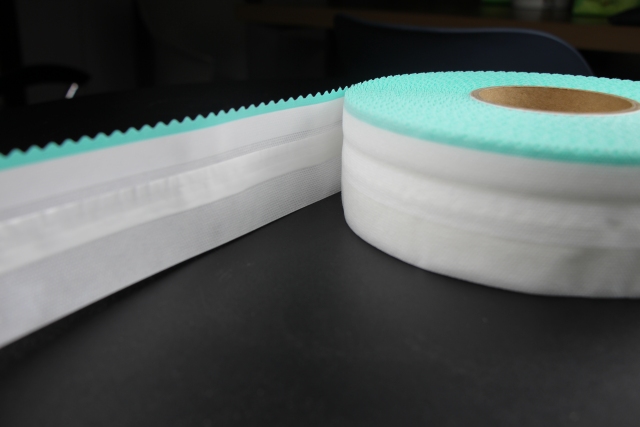

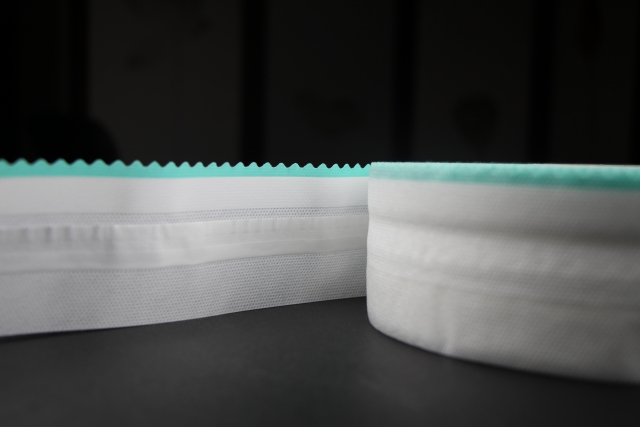

Diaper manufacturing is a highly specialized and demanding industry. With the increasing demand for superior comfort and functionality, non-woven side tapes have emerged as a popular choice due to their softness, flexibility, and ease of application. However, integrating non-woven side tapes into diaper production poses unique challenges. Below, we examine the key hurdles manufacturers face when using this material.

1.Raw Material Quality and Consistency

Non-woven materials are created through processes like spunbonding, meltblown, or hydroentanglement, each offering varying levels of strength, flexibility, and softness. Ensuring consistent quality and performance of these materials is a critical challenge. Variations in fiber bonding, thickness, or tensile strength can lead to manufacturing defects or diminished product performance. Additionally, sourcing high-quality raw materials at competitive prices can be difficult, especially as global demand for non-woven fabrics increases across industries.

2. Adhesion and Compatibility with Core Materials

The bonding process between non-woven side tapes and the diaper’s core structure is complex. Manufacturers often rely on advanced adhesive technologies, such as hot melt adhesives, to secure the side tapes to the polyethylene backsheet. However, achieving a strong yet flexible bond requires precise control of temperature, adhesive application rates, and pressure during lamination. Poor adhesion can result in delamination, reducing the diaper’s durability and user satisfaction. Moreover, adhesives must be compatible with both the non-woven material and the other diaper components, which necessitates extensive testing and formulation adjustments.

3. Production Line Integration

Incorporating non-woven side tapes into high-speed production lines demands advanced machinery and precise synchronization. Non-woven materials, being lightweight and flexible, are prone to wrinkling, misalignment, or tearing during high-speed operations. Automated systems need to detect and correct these issues in real time, requiring sophisticated sensor technology and control software. Additionally, modifying existing production lines to accommodate non-woven tapes can be costly and time-consuming, particularly for manufacturers upgrading from traditional plastic-based side tapes.

4. Environmental and Sustainability Concerns

As sustainability becomes a key focus in consumer products, manufacturers face pressure to use eco-friendly materials in their diaper designs. While non-woven side tapes are valued for their performance, many are derived from petroleum-based polymers, raising concerns about their environmental impact. Developing biodegradable or recycled alternatives is an ongoing challenge. Additionally, balancing environmental objectives with cost efficiency and product performance can lead to trade-offs that complicate decision-making.

5. Durability Versus Comfort

One of the major appeals of non-woven side tapes is their softness, which enhances user comfort. However, this softness can come at the expense of durability. The side tapes must withstand repeated fastening and unfastening while maintaining their structural integrity. Achieving this balance between comfort and durability involves meticulous material selection and design optimization. Manufacturers must also account for user variability, including differences in infant activity levels and body shapes, which can further stress the side tapes.

6. Cost Pressures and Market Expectations

Finally, producing diapers with non-woven side tapes involves higher material and operational costs than traditional alternatives. At the same time, manufacturers face significant pressure to maintain competitive pricing in a crowded market. Brands must strike a delicate balance between innovation and affordability, investing in research and development to improve materials and processes without inflating retail prices. Meeting consumer expectations for performance, comfort, and sustainability adds another layer of complexity to cost management.

Conclusion

While non-woven side tapes offer significant advantages in diaper production, they also introduce a range of technical, operational, and financial challenges. From ensuring consistent material quality to addressing environmental concerns and cost pressures, manufacturers must navigate a complex web of requirements. By investing in advanced technologies, fostering supplier partnerships, and prioritizing sustainability, the diaper industry can overcome these hurdles and continue to deliver high-quality products to consumers.