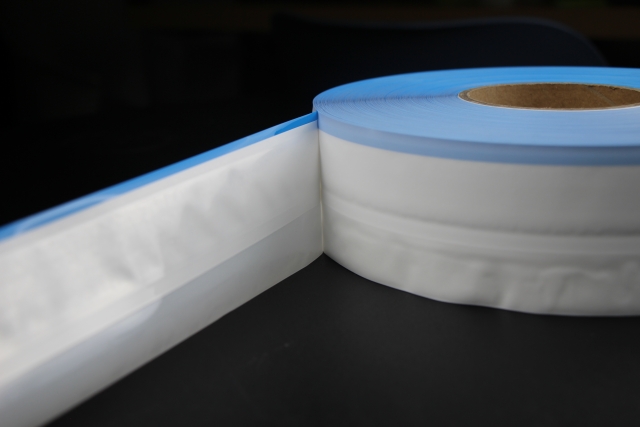

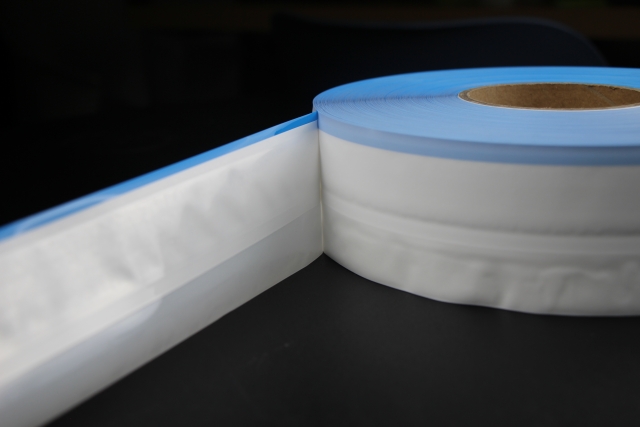

The selection of polypropylene (PP) side tape is an essential component in the design of diapers, as it plays a significant role in ensuring the fit, comfort, and functionality of the product. PP side tapes are used to fasten the diaper around the waist, securing it in place and preventing leaks while offering flexibility and comfort. However, when designing diapers for different sizes—such as newborn, infant, or toddler sizes—several factors must be considered in the selection of PP side tape to ensure optimal performance and comfort. These factors include tape strength, stretchability, softness, skin safety, adhesive properties, and environmental considerations. This article explores these critical factors and how they influence the choice of PP side tape in different diaper sizes.

1. Strength and Durability of PP Side Tape

One of the most important factors to consider when selecting PP side tape is the strength and durability of the material. PP side tapes need to securely fasten the diaper without causing discomfort or compromising the product's integrity. The strength of the side tape should be appropriate for the size and weight of the baby or child. For smaller sizes, such as newborn or size 1 diapers, the side tape needs to be less rigid but still strong enough to hold the diaper in place. In contrast, for larger diaper sizes intended for toddlers or older children, the PP side tape must offer greater tensile strength to accommodate the increased weight and activity levels.

The side tape's ability to withstand pulling, stretching, and general wear is critical for preventing leakage and ensuring the diaper stays intact during extended use. Manufacturers typically select PP tapes that offer a balance of high tensile strength and flexibility, enabling them to hold securely without being overly stiff. Furthermore, the durability of the PP side tape should not compromise the softness or comfort of the diaper, especially for more sensitive skin in smaller sizes.

2. Elasticity and Stretchability of PP Side Tape

The elasticity and stretchability of PP side tape are key factors to consider, particularly when designing diapers that need to accommodate a range of body shapes and sizes. Diapers are often made to fit a variety of body types, and side tape must be able to adjust and stretch to ensure a snug yet comfortable fit. This is particularly true for larger sizes, where babies and toddlers may have more active movements, such as crawling, walking, or running. The PP side tape should have some degree of stretchability to ensure that the diaper adapts to the movements of the child without becoming too tight, which can lead to discomfort or leakage.

For smaller sizes, stretchable PP side tapes should still provide a secure fit without causing undue pressure on the baby’s skin. It is important that the tape has a gentle yet firm stretch, allowing for a comfortable, custom fit that can accommodate slight changes in body shape. In diapers designed for larger children, PP side tape with higher elasticity is particularly important to allow for more flexibility and to provide a secure hold during increased physical activity. Additionally, the stretchability of the tape must not result in the loss of its adhesive properties or affect the diaper's ability to stay securely fastened.

3. Softness and Skin Comfort

Comfort is a critical consideration in any diaper design, particularly for products intended for sensitive baby skin. The PP side tape should be soft enough to prevent skin irritation or discomfort, especially around the waist and thigh areas, where the tape comes into direct contact with the skin. In diapers for smaller babies, such as newborn and size 1 diapers, the PP side tape must be gentle and smooth to minimize the risk of chafing or skin damage. For this reason, PP side tapes used in these smaller sizes often feature softer coatings or lamination processes to ensure a non-abrasive feel against the skin.

For larger diaper sizes, while the PP side tape may need to be stronger and more durable, manufacturers must still ensure that it is soft enough for prolonged skin contact. The use of soft-touch coatings or additives like silicone or hypoallergenic materials can help reduce friction and provide a comfortable experience. A diaper with a softer PP side tape can also promote better skin breathability, reducing the likelihood of rashes or skin irritation, especially during warmer weather or extended wear periods.

4. Adhesive Properties and Performance

The adhesive properties of PP side tape are a crucial factor in ensuring the diaper stays securely fastened throughout the day or night. The adhesive used in the side tape must strike the right balance between strong adhesion and ease of removal. For diapers in smaller sizes, such as newborns, the tape needs to adhere firmly enough to secure the diaper but also be easy to remove without causing any damage to the diaper or discomfort to the baby. The adhesive should be skin-safe, non-toxic, and dermatologically tested to prevent skin irritation.

For larger diaper sizes, the adhesive needs to withstand more movement and the increased weight of the child. As children grow and become more active, there is greater potential for the tape to be subjected to higher stress and friction. Therefore, the adhesive properties should allow for a strong and reliable hold but still be adjustable, so caregivers can reposition the tape to achieve the best fit. Modern PP side tapes often feature advanced adhesives that allow for multiple reattachments without losing effectiveness, providing a better fit and reducing the chances of leaks.

5. Environmental Impact and Sustainability

With growing consumer awareness around environmental sustainability, the choice of materials used in PP side tapes is becoming increasingly important. Biodegradability and the use of eco-friendly materials are key considerations in selecting side tapes for diapers. The polypropylene (PP) itself is a type of plastic, and while it is durable and effective, its environmental impact can be significant, especially if disposed of improperly. Manufacturers are exploring alternative materials, such as biodegradable nonwoven fabrics, that can be incorporated into the side tape construction to reduce the environmental footprint of the product.

In addition to the base material, the environmental impact of the adhesives used in PP side tapes should also be taken into account. Eco-friendly adhesives that are free from harmful chemicals, such as formaldehyde, phthalates, or solvents, can help make the diaper more environmentally sustainable without compromising performance. The increasing push for sustainability in the diaper industry means that selecting PP side tapes with a focus on eco-friendly alternatives is an important step toward reducing waste and minimizing harmful effects on the environment.

6. Cost-Effectiveness and Production Considerations

Cost-effectiveness remains an essential factor when selecting PP side tape for diapers. Manufacturers need to strike a balance between performance, comfort, and production costs. The selection of PP side tapes must take into account material costs, as well as manufacturing processes. For smaller diaper sizes, the use of PP side tape may require simpler designs or smaller quantities of material, leading to lower production costs. In contrast, larger diaper sizes require more material and additional processing to ensure the side tape is strong, elastic, and comfortable.

In order to keep production costs manageable while still maintaining high standards of quality, manufacturers often choose PP side tapes that offer good performance at competitive prices. They may also focus on optimizing the manufacturing process by using automated systems that ensure consistent tape quality and efficient production rates. Cost-effectiveness does not mean sacrificing product quality; rather, it involves finding the best combination of materials and manufacturing processes that will meet the needs of consumers while keeping the final price within an acceptable range.

In conclusion, selecting the right PP side tape for diapers of different sizes involves carefully considering several factors, such as strength, elasticity, softness, adhesive performance, and environmental impact. By understanding how each of these factors interacts with the diaper's design, manufacturers can create a product that delivers both comfort and functionality. Whether for newborns or toddlers, choosing the appropriate PP side tape is crucial in ensuring that the diaper provides a secure, comfortable, and skin-friendly fit that supports both the well-being of the baby and the preferences of the caregiver.