Polypropylene (PP) side tape is an essential component in diaper manufacturing, playing a crucial role in ensuring the functionality and comfort of the final product. It is a material that manufacturers use to fasten and secure diapers, especially in the design of disposable diapers for babies and adults. The side tape allows the diaper to fit snugly around the waist and legs, preventing leaks and ensuring ease of use. This article will explore what PP side tape is, its properties, how it is integrated into the diaper production process, and why it is vital in creating high-quality, comfortable, and reliable diapers.

Understanding Polypropylene (PP) Side Tape

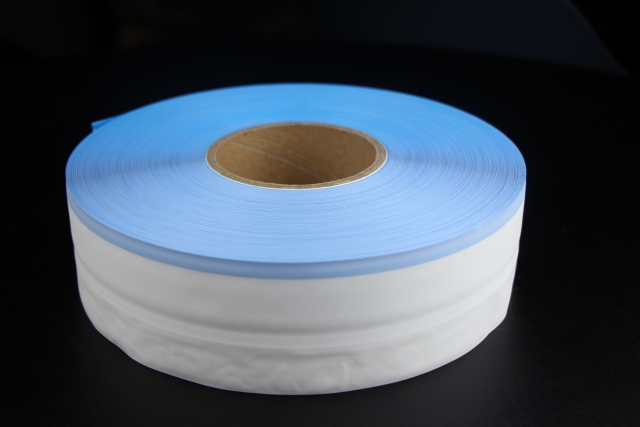

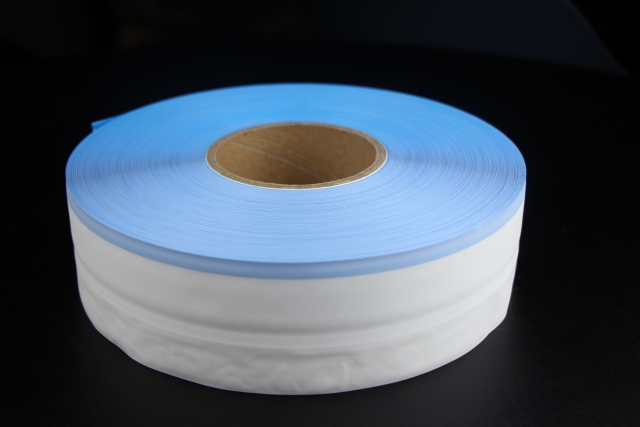

PP side tape is made from polypropylene, a thermoplastic polymer that is widely used in various industries due to its durability, flexibility, and resistance to moisture. In diaper manufacturing, PP side tape functions as a fastener, providing the necessary strength to hold the diaper in place while also allowing it to be easily adjusted and refastened multiple times. Polypropylene’s light weight and high resistance to fatigue make it an ideal material for applications requiring repeated use, such as diaper closures.

The side tape typically consists of two layers: the adhesive layer and the PP backing layer. The adhesive layer ensures the tape sticks securely to the diaper’s outer surface, while the PP backing provides the structural strength needed to withstand the stresses of opening and closing. The tape’s design allows for repeated fastening without losing its adhesive properties, which is crucial for parents who need to adjust the diaper multiple times during use.

The Role of PP Side Tape in Diaper Manufacturing

In the diaper manufacturing process, PP side tape is applied towards the end of production after the diaper’s absorbent core, top sheet, and back sheet have been assembled. The side tape is attached to the back wings of the diaper, enabling it to wrap around the baby or adult's waist and adhere to the front portion of the diaper. This step is performed using high-speed machinery designed to precisely position the tape to ensure consistent performance across each diaper.

One of the key factors in the effectiveness of PP side tape is its ability to maintain adhesion even when exposed to moisture and body movement. Diapers are designed to handle varying conditions, including frequent motion, friction, and contact with fluids. The PP side tape must be strong enough to keep the diaper securely in place while also being gentle on the skin to prevent irritation. High-quality PP side tape achieves this balance by combining strong adhesive properties with a smooth surface finish that reduces the risk of discomfort or chafing.

Advantages of Using PP Side Tape in Diapers

The use of PP side tape in diaper manufacturing offers several advantages, both for manufacturers and consumers. From a production standpoint, PP side tape is cost-effective and can be easily integrated into automated assembly lines. Its lightweight nature helps reduce material costs, while its durability ensures that fewer defective products are produced. Additionally, PP side tape can be customized with different levels of adhesive strength, allowing manufacturers to tailor the diaper’s performance to specific market needs, such as for active toddlers or adults with mobility challenges.

For consumers, the main benefits of PP side tape lie in its reusability and convenience. Diapers with PP side tape can be opened and closed multiple times without losing their fastening ability, which is particularly useful for parents who may need to check or adjust the diaper without fully removing it. Furthermore, the flexibility and softness of the tape enhance the overall comfort of the diaper, helping to prevent irritation or pressure marks on sensitive skin. PP side tape also contributes to a better fit, ensuring that the diaper stays in place and provides effective leak protection.

Quality Control and Testing of PP Side Tape

To ensure that PP side tape meets the high standards required for diaper manufacturing, it undergoes rigorous quality control and testing. Manufacturers test the tape for several key attributes, including peel strength, shear strength, and adhesion durability. Peel strength refers to the amount of force needed to remove the tape from the diaper’s surface, while shear strength measures the tape’s ability to withstand lateral forces without shifting or coming loose. Both of these properties are crucial for maintaining the tape’s functionality during the diaper’s intended use.

Adhesion durability is tested under various conditions to simulate real-world scenarios, such as exposure to moisture, heat, and movement. This ensures that the PP side tape will perform consistently, even under demanding conditions. Additionally, manufacturers often conduct skin sensitivity tests to verify that the tape will not cause irritation or allergic reactions when in contact with delicate skin. Ensuring that PP side tape meets these stringent standards is vital for producing diapers that are both safe and effective for consumers.

Sustainability and Future Trends in PP Side Tape

As the diaper industry continues to evolve, sustainability has become a significant concern for both manufacturers and consumers. Many diaper manufacturers are exploring ways to make their products more environmentally friendly, and this includes innovations in PP side tape technology. While traditional PP is not biodegradable, research is underway to develop more sustainable alternatives that offer similar performance characteristics. For example, some manufacturers are experimenting with bio-based polymers or recyclable adhesives to reduce the environmental impact of disposable diapers.

Another emerging trend is the use of stretchable PP side tape, which offers enhanced flexibility and comfort by allowing the diaper to adjust more easily to the wearer’s movements. This type of tape can help improve the fit of the diaper and reduce the likelihood of leaks, especially for active individuals. As consumer demands continue to shift towards more sustainable and high-performance diaper products, the role of PP side tape in meeting these expectations will remain a key focus for innovation.

Conclusion

PP side tape is a critical component in diaper manufacturing, providing the necessary functionality for secure fastening, adjustability, and comfort. Its durable and lightweight properties, combined with the ability to be reused multiple times, make it an ideal material for use in disposable diapers. By understanding the role of PP side tape, manufacturers can continue to improve the quality and performance of their products, while also exploring new ways to enhance sustainability. As the industry moves towards more eco-friendly solutions, innovations in PP side tape technology will play a central role in shaping the future of diaper manufacturing.