Disposable diapers are a product of modern innovation, designed for convenience and comfort. One of the key components in disposable diapers is the fastening system, typically achieved through the use of disposable tape. This tape is crucial for keeping the diaper in place, ensuring it fits securely around the baby's waist, and allowing for adjustments as needed. The materials used for this disposable tape must balance durability, elasticity, skin-friendliness, and cost-effectiveness. This article will explore the most commonly used materials in disposable tape for diapers, their properties, and why they are chosen.

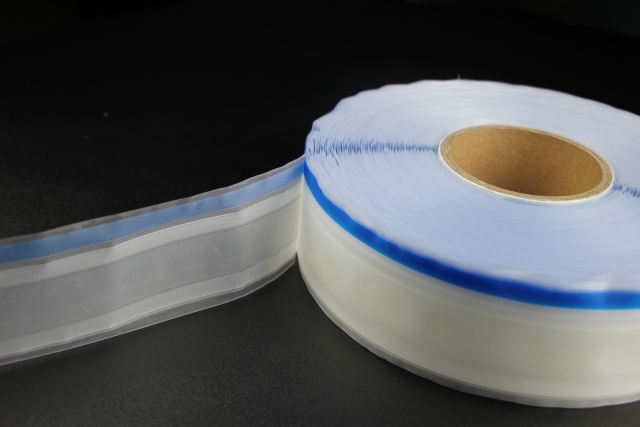

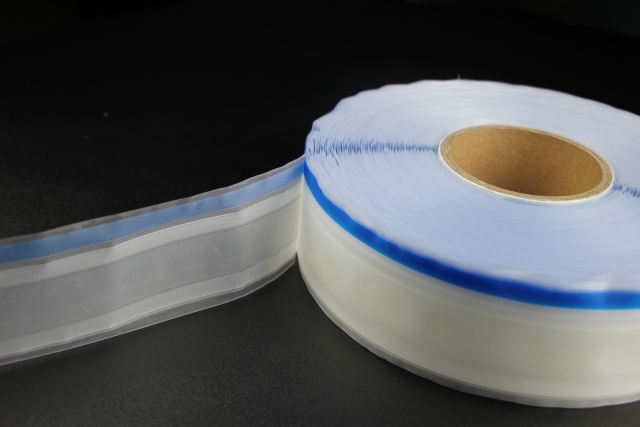

Polyethylene (PE) Films

Polyethylene (PE) films are one of the most widely used materials for disposable tape in diapers. PE is a thermoplastic polymer that is lightweight, flexible, and resistant to moisture. These qualities make it ideal for use in the outer layer of the diaper tape. The film provides a smooth surface that adheres well to adhesives, making it easy to open and close the diaper multiple times. Additionally, PE films are known for their excellent barrier properties, preventing moisture from passing through while remaining breathable, which is important for maintaining the baby’s comfort. PE films also have a low cost and are easy to produce, making them an economically viable option for large-scale diaper manufacturing.

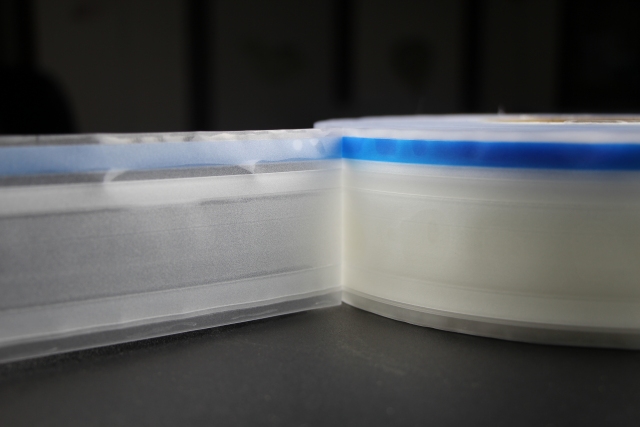

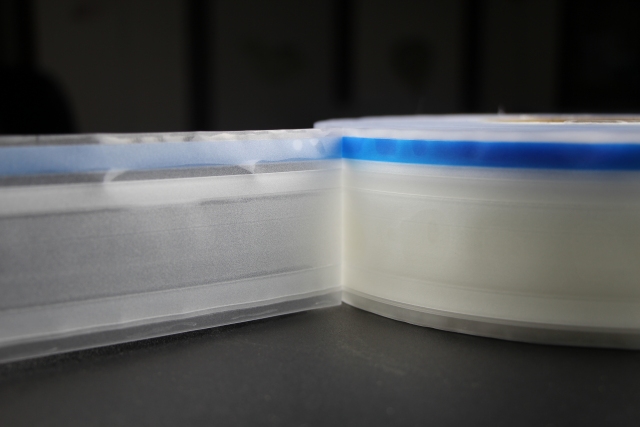

Polypropylene (PP) Nonwoven Fabric

Another common material used in diaper tapes is polypropylene (PP) nonwoven fabric. PP is another thermoplastic polymer that is known for its strength, elasticity, and resistance to chemicals. Nonwoven PP fabric is soft to the touch, making it suitable for use in contact with the baby’s skin. In disposable diaper tapes, PP nonwoven is often used in the landing zone – the area where the tape adheres when closed. This material allows for a strong but gentle grip, preventing the tape from easily coming undone while still providing flexibility for movement. Nonwoven PP is also breathable, helping to reduce the risk of skin irritation or rashes caused by prolonged exposure to moisture.

Acrylic and Rubber-Based Adhesives

Adhesives are an essential part of disposable diaper tapes, ensuring that the fastening system holds securely during use. The two main types of adhesives used are acrylic and rubber-based adhesives. Acrylic adhesives are known for their strong bonding properties and resistance to environmental factors such as temperature and humidity. They are often used in diaper tapes for their ability to provide a long-lasting hold while remaining easy to peel off when needed. Rubber-based adhesives, on the other hand, are known for their flexibility and elasticity. These adhesives are typically used in areas of the diaper that require stretch, such as the side tabs, to allow the diaper to conform to the baby's movements without breaking the seal.

Elastomeric Materials

To enhance the flexibility and fit of the diaper, elastomeric materials are often incorporated into the tape system. These materials, such as spandex or latex, provide stretchability to the diaper’s fastening system, ensuring a snug fit around the baby’s waist and legs. Elastomeric materials are highly elastic, meaning they can stretch and return to their original shape without losing their strength. This elasticity is crucial for accommodating a baby’s movements, as diapers need to expand and contract throughout the day without compromising the seal. Spandex, in particular, is commonly used for its soft texture and high elasticity, making it a preferred material in premium diaper brands.

Release Coatings and Silicone-Based Films

In some cases, release coatings or silicone-based films are applied to the surface of the diaper tape to improve its functionality. These coatings help to reduce the adhesive's tackiness when the tape is not in use, allowing it to be easily peeled off and repositioned without damaging the diaper’s structure. Silicone-based films are particularly useful in creating a smooth, non-stick surface that facilitates easy handling during diaper changes. Additionally, these coatings can help protect the adhesive from contamination by dust or oils, ensuring that the tape maintains its effectiveness throughout its use. By incorporating these specialized materials, manufacturers can improve the user experience and reliability of disposable diaper tapes.

Conclusion

In summary, the materials used in disposable diaper tapes are carefully selected to provide a balance of strength, flexibility, comfort, and cost-effectiveness. Polyethylene (PE) films and polypropylene (PP) nonwoven fabrics form the structural components, offering durability and skin-friendly properties. Acrylic and rubber-based adhesives ensure a secure fit, while elastomeric materials like spandex provide flexibility and a snug fit. Finally, release coatings and silicone-based films enhance the usability and functionality of the tape. By using this combination of materials, manufacturers can produce disposable diaper tapes that meet the needs of both parents and babies, ensuring a secure, comfortable fit with each use.