Comprehensive Overview of the Closed-Loop System for Diapers

In modern parenting, diapers have become an indispensable item. However, with the widespread use of diapers, the environmental issues they bring have gradually attracted public attention. To address this problem, the closed-loop system for diapers has been developed. This article will explore the scientific principles and practical applications of the closed-loop system for diapers from three aspects: raw materials, usage methods, and environmental issues.

1. Composition of Raw Materials in Diapers

The raw materials of diapers mainly consist of three parts: the absorbent core, the surface layer, and the outer layer. The absorbent core is usually made of wood pulp and superabsorbent polymers (such as SAPs), which are responsible for quickly absorbing and locking in urine, keeping the surface dry. The surface layer is made of soft non-woven fabric that comes into direct contact with the baby’s skin. It needs to be breathable and soft to prevent allergies and discomfort. The outer layer is typically made of a waterproof and breathable film, effectively preventing leakage while allowing internal moisture to escape, thus enhancing comfort.

In the closed-loop system, more emphasis is placed on the environmental sustainability of raw materials. Traditional diapers often use wood pulp sourced from trees, whereas the closed-loop system explores the use of renewable resources such as bagasse or bamboo fibers as alternatives. Additionally, the use of superabsorbent polymers is shifting towards biodegradable materials to reduce long-term environmental impact.

2. Usage Methods and Convenience of Diapers

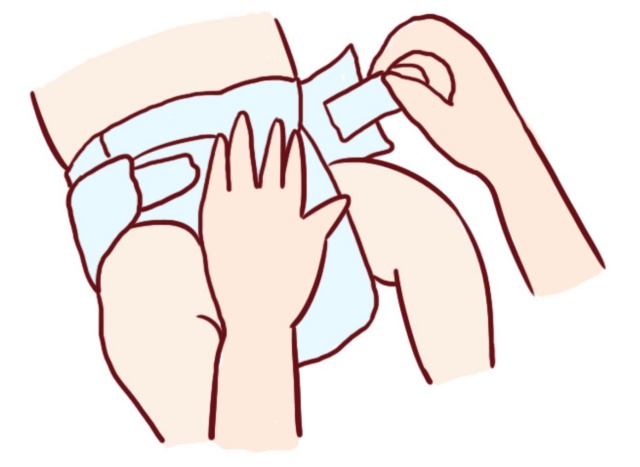

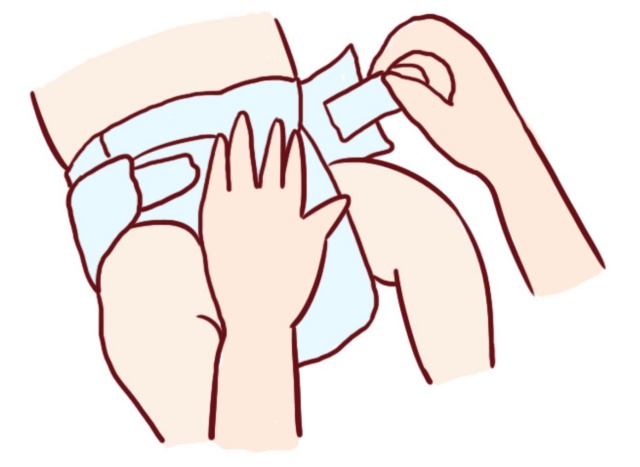

The use of diapers is straightforward, mainly involving wearing and changing. For new parents, choosing the correct size and mastering the technique of wearing diapers is crucial. Diapers should fit snugly around the baby’s waist and thighs to prevent leakage. Regular checks and timely changes can effectively prevent diaper rash and other issues.

The closed-loop system has optimized the design for usage, such as introducing products with "wetness indicators" that change color when the diaper is full, reminding parents to change it. This design not only enhances convenience but also helps reduce diaper waste. Additionally, some diapers within the closed-loop system use reusable adhesive strips, allowing for multiple adjustments as needed, further extending the product's lifespan.

3. Environmental Challenges of the Closed-Loop System for Diapers

With the increase in diaper usage, the issue of disposing of used diapers has become increasingly severe. Statistics show that traditional diapers can take hundreds of years to degrade, placing immense pressure on the environment. One of the core goals of the closed-loop system is to reduce this environmental burden.

The environmental strategies of the closed-loop system focus on two main aspects: material selection and waste disposal. In terms of material selection, the system favors biodegradable materials, and some diapers are even made entirely of plant-based materials, significantly reducing landfill stress. In waste disposal, the closed-loop system advocates establishing a diaper recycling mechanism, where professional institutions can handle used diapers by breaking them down into compostable materials or converting them into energy, thus achieving resource reuse.

4. Future Development Directions for the Closed-Loop System

As technology advances and environmental awareness grows, the future of the closed-loop system for diapers will become increasingly intelligent and eco-friendly. Future diapers may further integrate IoT technology, using sensors to monitor humidity and temperature in real-time and automatically alerting parents when it's time for a change. Moreover, the development of fully biodegradable materials will promote the widespread use of completely degradable diapers, effectively eliminating the environmental pollution caused by traditional diapers.

The recycling mechanism of the closed-loop system will also become more refined. Through collaboration with governments and businesses, nationwide or regional diaper recycling networks can be established, ensuring that diapers are efficiently recycled and processed after use, creating a truly closed-loop industry chain. Additionally, as environmental regulations become stricter, manufacturing companies will focus more on the environmental performance of their products, driving the entire industry towards sustainable development.

5. The Social Significance of the Closed-Loop System for Diapers

The closed-loop system for diapers is not just a technological and environmental innovation; it also holds significant social value. First, it responds to the urgent need for environmental protection in modern society, reducing waste and lowering resource consumption, thereby leaving a healthier planet for future generations. Second, the system promotes the development and application of new eco-friendly materials, driving the growth of related industries, creating more job opportunities, and generating economic value.

More importantly, the closed-loop system raises public environmental awareness. By understanding this system, more families are beginning to realize the importance of reducing waste and choosing eco-friendly products in their daily lives. This shift in mindset will help propel society toward a greener and more sustainable future.

In summary, the closed-loop system for diapers represents a major innovation in the diaper industry. It not only enhances the user experience but also makes significant contributions to environmental protection. As technology continues to advance and societal demands for environmental protection increase, the closed-loop system for diapers will play an even greater role, becoming a key driver of sustainable development.