Author:Hengdaxin Diaper Material SupplierFROM:Diaper Materials Manufacturer TIME:2024-08-05

Choosing the right raw materials for baby diapers is crucial for ensuring comfort, absorbency, and overall performance. Manufacturers must consider various factors such as safety, softness, moisture absorption, and environmental impact. This guide will delve into the key aspects to consider when selecting raw materials for baby diapers.

The absorbent core is the heart of a baby diaper, responsible for locking in moisture and keeping the baby dry. Superabsorbent polymers (SAP) are commonly used for their ability to absorb and retain liquid. Manufacturers must choose SAPs that are not only highly absorbent but also safe for prolonged contact with a baby’s skin.

The outer layer of a diaper is usually made from nonwoven fabrics. These materials need to be breathable to prevent diaper rash and discomfort. Polypropylene and polyester are popular choices due to their softness, strength, and ability to wick moisture away from the skin.

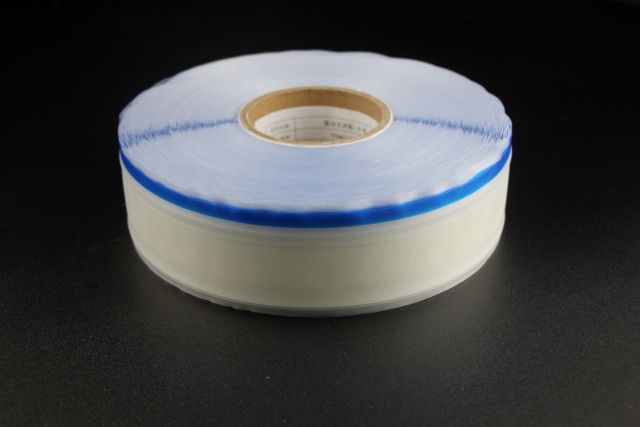

The inner layer of a diaper should be gentle on the baby’s delicate skin. Materials like spunbond nonwovens or perforated films are used to create a soft, dry surface that keeps moisture away from the skin while allowing liquids to pass through to the absorbent core.

Elastic materials are essential for providing a snug and comfortable fit around the baby’s legs and waist. Spandex or elastane is commonly used for its stretchability and resilience. Manufacturers must ensure that the elastic materials used are hypoallergenic and do not cause irritation.

Diapers typically feature adhesive tapes or hook-and-loop closures to secure the diaper in place. The materials used for these closures should be strong enough to hold the diaper securely without causing discomfort or skin irritation. Adhesives must be non-toxic and designed for easy removal and repositioning.

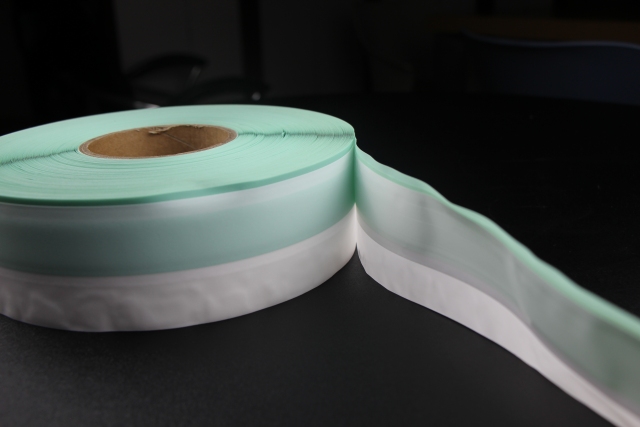

The acquisition and distribution layer helps to distribute urine evenly throughout the diaper and enhance overall absorbency. Nonwoven fabrics treated with surfactants or with special embossing patterns are used to quickly distribute liquid to the absorbent core while minimizing rewet and leakage.

Ensuring breathability in diaper materials is crucial for maintaining skin health and preventing diaper rash. Breathable materials allow air to circulate, reducing heat buildup and keeping the baby’s skin dry and comfortable. Micro-perforated films and breathable nonwoven fabrics are commonly used to achieve this.

With increasing awareness of environmental sustainability, diaper manufacturers are exploring eco-friendly alternatives for raw materials. Biodegradable materials, such as bamboo fibers or organic cotton, are gaining popularity for their reduced environmental impact. Manufacturers need to balance environmental considerations with the performance and safety requirements of baby diapers.

Choosing the right raw materials for baby diapers involves careful consideration of absorbency, comfort, safety, and environmental impact. By selecting high-quality materials such as superabsorbent polymers, breathable nonwovens, and eco-friendly alternatives, manufacturers can create diapers that provide optimal performance while ensuring the well-being of babies. Ultimately, the choice of diaper materials plays a critical role in enhancing the overall user experience and maintaining customer satisfaction.