Author:Hengdaxin Diaper Material SupplierFROM:Diaper Materials Manufacturer TIME:2024-08-07

Sanitary pads are essential hygiene products used by women worldwide. The production of sanitary pads involves various raw materials, each serving crucial functions to ensure comfort, absorbency, and safety. Understanding these raw materials and their applications is fundamental to enhancing the quality and effectiveness of sanitary pads.

Superabsorbent polymers, commonly known as SAPs, are one of the key components in sanitary pads. These polymers have the remarkable ability to absorb and retain large amounts of liquid relative to their own mass. Typically made from acrylic acid and its salts, SAPs ensure that menstrual fluid is rapidly absorbed and locked away, preventing leaks and keeping the surface dry.

Wood pulp, derived from softwood trees, is another essential raw material in sanitary pads. It is processed into fluffy fibers known as cellulose fluff. These fibers enhance the absorbent capacity of pads, providing a soft and comfortable layer that absorbs menstrual fluid and distributes it evenly throughout the pad. Cellulose fluff is biodegradable, making it environmentally friendly.

Non-woven fabrics are used extensively in the outer layers of sanitary pads. These fabrics are made from synthetic fibers like polypropylene, polyester, or natural fibers such as cotton. Non-wovens provide a soft, breathable surface that allows moisture to pass through while keeping the skin dry and comfortable. They also contribute to the structural integrity of the pad.

Adhesives and sealants are crucial for bonding different layers of materials in sanitary pads. Hot melt adhesives are commonly used due to their fast bonding properties and resistance to moisture. These adhesives ensure that the pad maintains its shape and structure during use, preventing shifting or bunching.

The backsheet of a sanitary pad is typically made from breathable materials such as polyethylene or polypropylene. These materials are waterproof yet breathable, allowing air to circulate while preventing leakage. A breathable backsheet enhances comfort by reducing heat buildup and maintaining a dry feeling against the skin.

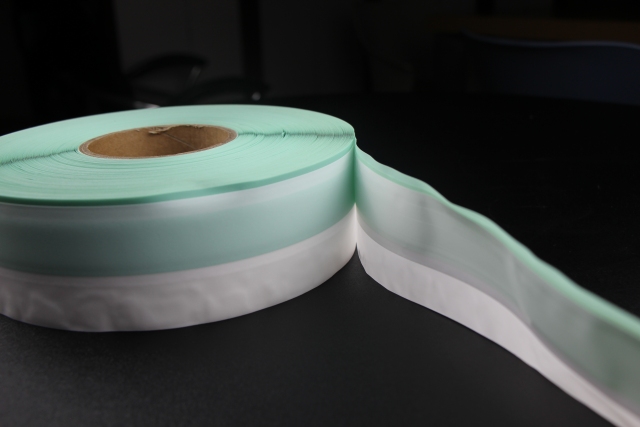

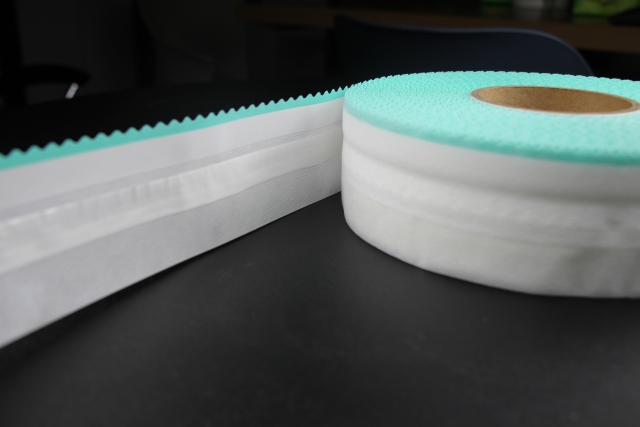

Release paper is used as a protective layer on adhesive surfaces of sanitary pads. It prevents the adhesive from sticking to other surfaces before use and ensures that the pad remains securely attached to undergarments during wear. Release paper is often coated with silicone to facilitate easy removal.

Fragrances and odor neutralizers are sometimes added to sanitary pads to provide a fresh scent and neutralize unpleasant odors associated with menstrual flow. These additives enhance user comfort and confidence, especially during heavier flows.

Packaging materials for sanitary pads play a crucial role in maintaining product hygiene and convenience. They are designed to protect pads from contamination and damage during storage and transportation. Packaging materials may include plastic films, wrappers, and cartons that provide information and instructions for use.

In conclusion, the raw materials used in the production of sanitary pads each serve unique functions that contribute to the overall performance and comfort of the product. From superabsorbent polymers and wood pulp for absorbency to non-woven fabrics and breathable backsheets for comfort and protection, every component plays a vital role. Manufacturers continue to innovate with new materials and technologies to enhance the effectiveness and sustainability of sanitary pads, ensuring that women have access to safe and reliable hygiene products.