Author:Hengdaxin Diaper Material SupplierFROM:Diaper Materials Manufacturer TIME:2024-07-25

For diaper closure systems, strong hold, softness and breathability are crucial, yet it can be hard to excel at each quality without tradeoffs. Learn how the latest closure system advances help diaper manufacturers to achieve optimal performance and processing.

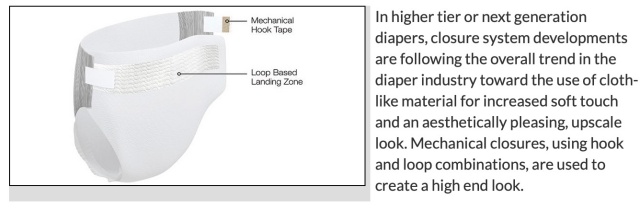

Mechanical hook tape is designed to be applied on a loop-based landing zone, applied on the diaper’s front.

- Closure system: The landing zone, together with a mechanical hook tape, forms a closure system.

Diaper Market Trends Influence Closure Design

The diaper industry is on a growth trajectory to reach $52.2 billion in global sales by 2017, according to Transparency Market Research. To capture a share of this expanding market, diaper manufacturers are focusing on ways to differentiate themselves by offering higher levels of comfort and performance.

In its 2014 diaper industry trends article, management consultant firm Price Hannahighlighted some important connections that major diaper manufacturers want consumers to make between their babies’ well-being and product attributes such as softness and secure fit. A diaper should have similar qualities to cotton underwear—super soft, comfortable and breathable and will not irritate the baby’s skin.

This is one reason behind the market’s continuous search for softer materials. Soft nonwoven backsheet material that promotes comfort, for instance, has emerged as a successor to plastic backsheets. Breathable materials also are a priority as diaper brands seek to alleviate the skin clamminess and potential diaper rashes that can occur when a baby’s skin touches materials with little to no air permeability. These trends have led to increasing popularity of cloth-like and breathable backsheets, which has driven the industry to explore new requirements for the accompanying diaper closure systems.

However, not all mechanical closure systems are created equally. In light of some recent closure system advances, there are obvious and subtle differences that meaningfully affect performance. For example, the traditional hook and loop closures that were first on the scene offer a strong hold. But, with their typically nylon construction, these lock loop systems offer little softness. They also lack breathability because of the filmic laminate layer that lends stability to their landing zone.

Closures made of nonwoven loop landing zone material, allowed diaper manufacturers to solve to the issues of breathability and softness. At the same time, these closure systems presented some performance and cost challenges. To compensate for the weaker holding interaction between the loop and hook tape, some manufacturers used wide hook tape components. Greater material volume requirements could drive up overall closure system costs while the high air permeability of the landing zone material could present processing complications.

The latest generation mechanical diaper closure system addresses demands for softness, breathability and strong hold performance.thanks to a specialized multilayer construction. This construction enables the material to be processed on high speed diaper manufacturing lines. It can be also repositioned and reclosed multiple times due to its high peel and shear performance.

Peel performance in first generation of nonwoven loop closure systems was lower than in lock loop closure systems. To meet consumer demands, diaper manufacturers are looking for similar high peel performance with lock loop closure systems along with the softness and breathability of nonwoven loop closure systems.n