Author:Hengdaxin Diaper Material SupplierFROM:Diaper Materials Manufacturer TIME:2024-07-25

Functions and Applications of Diaper Production Raw Materials

Diapers are essential products used globally to maintain hygiene and comfort, particularly for infants, toddlers, and adults with various needs. The production of diapers involves a variety of raw materials, each serving specific functions to ensure the effectiveness, comfort, and absorbency of the final product. Understanding these raw materials and their applications is crucial for manufacturers aiming to produce high-quality diapers that meet consumer demands.

Superabsorbent polymers, commonly abbreviated as SAPs, are a key component in modern diaper production. These polymers are designed to absorb and retain large amounts of liquid relative to their own mass. Typically made from acrylic acid and sodium hydroxide, SAPs can absorb up to 30 times their weight in liquid. This property makes them highly effective in enhancing the absorbency of diapers, keeping the skin dry and reducing the risk of diaper rash.

Polypropylene and polyethylene are widely used in diaper production for their properties as non-woven fabrics. These materials are used in the inner and outer layers of diapers due to their softness, flexibility, and ability to repel water. PP and PE layers help in keeping the moisture inside the diaper while allowing air circulation, thus maintaining skin dryness and comfort for the wearer.

Fluff pulp is a type of wood pulp that has been processed to have high absorbency and softness. It is a crucial component of the absorbent core in diapers. Fluff pulp fibers are designed to rapidly absorb liquid and distribute it evenly throughout the core, preventing leaks and ensuring that the diaper remains dry on the surface. This material is biodegradable and sourced from sustainable forestry practices, aligning with eco-friendly diaper production trends.

Adhesives play a significant role in diaper construction, holding different parts of the diaper together such as the elastic waistband, closures, and attachment tabs. Hot melt adhesives are commonly used due to their quick bonding properties and resistance to moisture. These adhesives ensure that the diaper maintains its shape and structure during use, enhancing comfort and preventing leaks.

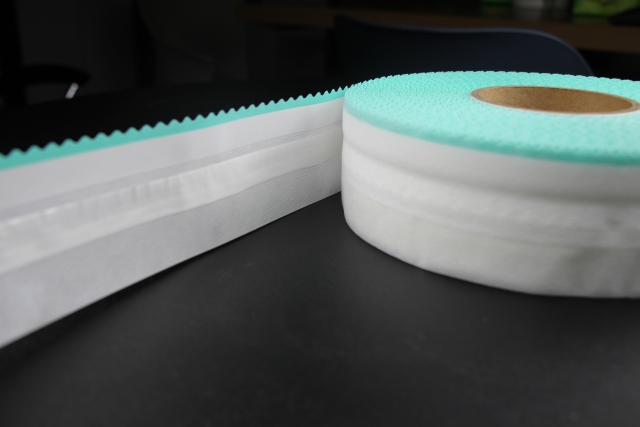

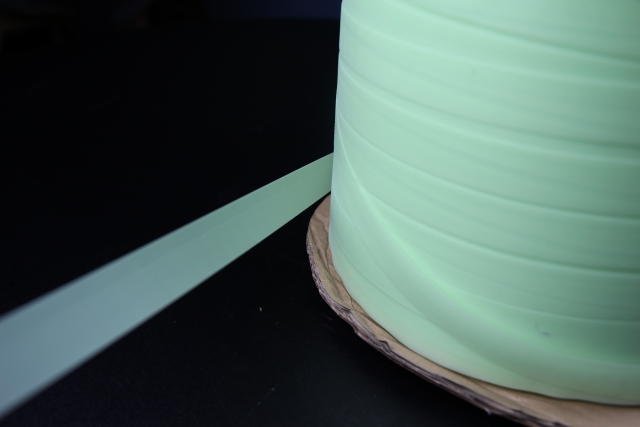

Elastic materials are essential for providing a snug and comfortable fit around the legs and waist of the diaper wearer. Typically made from synthetic rubber or elastane fibers, elastics are integrated into the diaper design to prevent leaks and provide flexibility during movement. Proper placement and tension of elastic materials are critical in ensuring that the diaper fits securely without causing discomfort or leaving marks on the skin.

Fragrances and lotions are often added to diapers to enhance the overall experience for both the wearer and caregiver. Fragrances help mask odors, creating a more pleasant environment, while lotions can soothe and protect sensitive skin. Manufacturers carefully select these additives to ensure they are hypoallergenic and safe for prolonged skin contact, maintaining the integrity of the diaper as a hygienic product.

Ink and colorants are used primarily for decorative purposes on the outer layers of diapers. These materials are applied using safe printing methods that ensure they do not transfer onto the skin or clothing. Colorful designs and characters printed on diapers can make them more appealing to children and caregivers, adding an element of fun while maintaining the functionality and performance of the product.

Backsheet materials form the outer layer of the diaper and play a crucial role in preventing leaks and ensuring the diaper's overall integrity. Typically made from breathable materials like polyethylene film, backsheet materials are designed to be waterproof yet allow vapor transmission, maintaining airflow and reducing the risk of skin irritation. The selection of backsheet materials is critical in achieving a balance between comfort, durability, and performance in various environmental conditions.

In conclusion, the raw materials used in diaper production are meticulously selected and engineered to fulfill specific functions that contribute to the overall performance, comfort, and safety of the product. From superabsorbent polymers that enhance absorbency to soft non-woven fabrics that provide comfort and dryness, each material plays a vital role in meeting the diverse needs of consumers worldwide. As diaper technology continues to advance, so too will the innovation and refinement of these raw materials, ensuring that diapers remain effective, reliable, and essential products in maintaining hygiene and comfort.