Author:Hengdaxin Diaper Material SupplierFROM:Diaper Materials Manufacturer TIME:2024-07-25

The evolution of frontal tape for baby diaper materials has been a crucial aspect of improving convenience, comfort, and functionality in infant care products. Over the years, advancements in materials science, adhesives, and consumer preferences have driven significant innovations in diaper closure systems. This article explores the journey of frontal tapes, from their early beginnings to modern-day solutions, highlighting key developments and their impact on the diaper industry.

In the early stages of diaper manufacturing, pins were commonly used to secure cloth diapers. However, the introduction of adhesive tapes revolutionized the industry. These tapes provided a simpler and more secure method of fastening diapers, significantly enhancing convenience for caregivers.

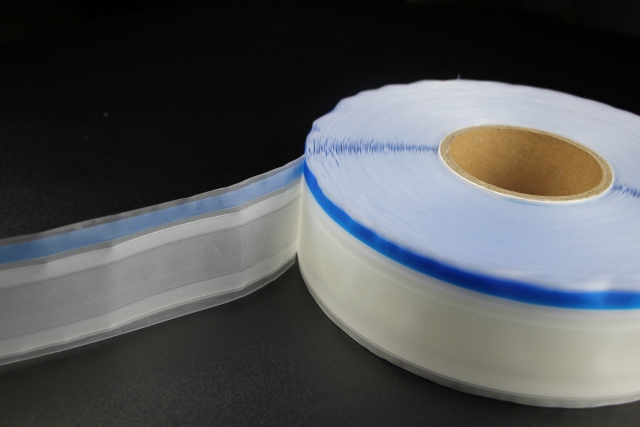

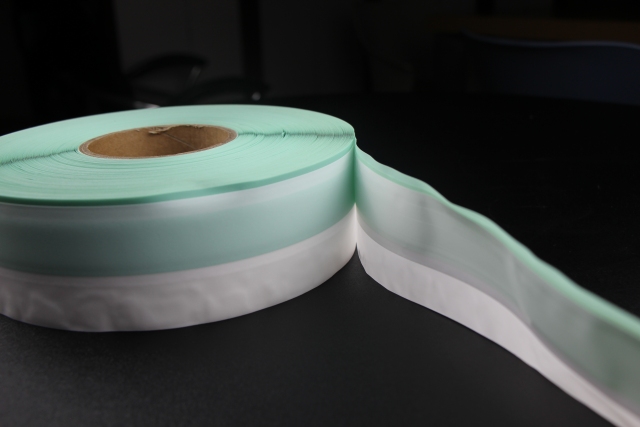

Initially, frontal tapes were made from plastic materials. These tapes offered basic functionality but often lacked flexibility and comfort. As consumer demands shifted towards softer and more breathable materials, non-woven fabrics emerged as a preferred choice. These materials not only improved comfort but also enhanced the overall performance of diaper tapes.

Advancements in adhesive technology have played a pivotal role in the evolution of frontal tapes. Early adhesives were primarily rubber-based and offered limited adhesive strength and durability. Modern adhesive formulations, such as pressure-sensitive adhesives (PSAs), provide strong adhesion to diaper surfaces while allowing for easy removal without causing discomfort to the baby's delicate skin.

Designing effective frontal tapes goes beyond adhesive strength. Ergonomic considerations, such as tape placement and width, directly impact user experience. Manufacturers now focus on creating tapes that are easy to grip, align, and adjust, ensuring a snug fit that prevents leaks and enhances comfort for infants.

With growing environmental awareness, there has been a shift towards sustainable diaper materials. Biodegradable tapes made from plant-based polymers and recyclable materials are gaining popularity. These tapes not only reduce environmental impact but also cater to eco-conscious consumers seeking greener diapering solutions.

Frontal tapes play a crucial role in ensuring diaper performance. Innovations in moisture management technology help to keep the diaper surface dry, minimizing the risk of diaper rash and discomfort for babies. Enhanced leak protection features, such as elastic tapes and advanced closure systems, further improve the reliability of diaper tapes.

Compliance with stringent safety and regulatory standards is essential for diaper manufacturers. Frontal tapes must meet requirements for skin contact safety, adhesive strength, and material composition. Adherence to these standards ensures that diaper tapes are safe and gentle on infants' sensitive skin.

Looking ahead, the future of frontal tapes lies in integrating smart technologies into diaper designs. Smart diapers equipped with sensors and indicators could provide real-time monitoring of a baby's health metrics, such as urine output and skin temperature. These innovations aim to enhance parental care and optimize diaper usage, marking a new era in diapering technology.

In conclusion, the evolution of frontal tapes for baby diaper materials has been driven by continuous innovation in materials, adhesives, design, and sustainability. From humble beginnings with adhesive tapes to sophisticated closure systems, these developments have significantly improved the comfort, convenience, and performance of baby diapers. As consumer preferences evolve and technological advancements continue, the future promises further enhancements in diapering solutions, ensuring optimal care for infants worldwide.