Author:Hengdaxin Diaper Material SupplierFROM:Diaper Materials Manufacturer TIME:2024-07-14

In recent years, along with the continuous growth of the diaper market, new material technologies related to diapers have also witnessed rapid development. Currently, there are a wide variety of diapers, mainly including open-close diapers and closed pull-up diapers, etc. This article mainly introduces the development and future new trends of the closure system of open-close diapers.

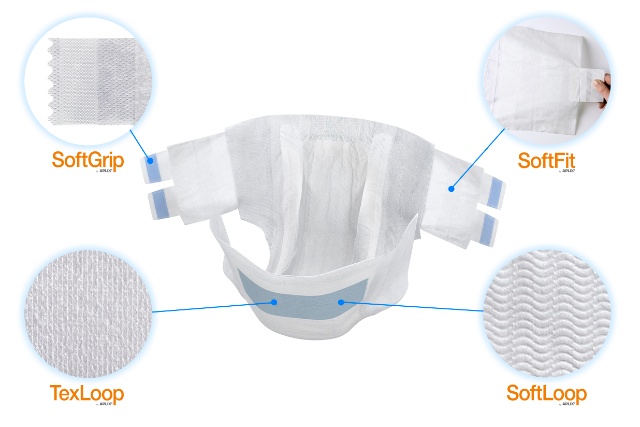

The open-close diaper closure system we are talking about mainly includes the following parts: the front waist sticker, the left and right waist stickers, and the elastic waistband. The entire closure system accounts for approximately 15% of the production cost of diapers, and its quality and performance are closely related to the quality and performance of the diaper product. The design of a perfect closure system is crucial to the comfort of wearing diapers, and it also helps maintain good fit of the diapers, effectively preventing side leakage and back leakage, allowing infants and young children to move freely when wearing diapers.

Development and current situation of the material technology of the front and side waist stickers With the development of new material technology, the development of the closure system of open-close diapers has also gone through several stages.

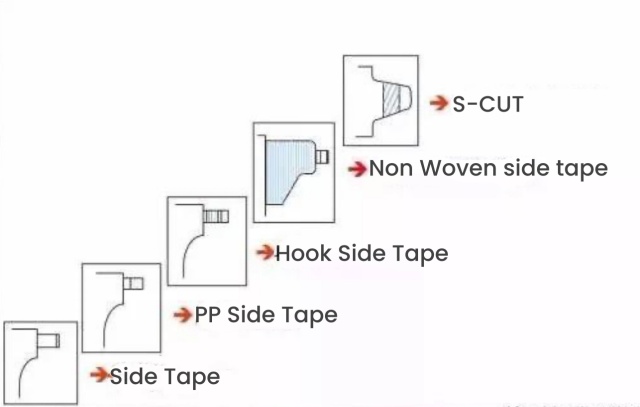

In the early days, the front waist sticker of diapers used a combination of polypropylene film and the compound tape of the left and right waist stickers. This combination effectively solved the problem of wearing diapers. However, after multiple uses of the compound tape, the adhesive surface was prone to contamination, resulting in a decrease in the adhesive viscosity. Its peeling and shearing effects would weaken, and it was easy to stick to the skin and difficult to be reused. Currently, only a few low-end diapers still use this structure.

After the appearance of reusable Velcro, the front waist sticker materials also have had various new developments. Among them, the most widely used is the woven mesh sticker made of polypropylene material. When used with Velcro, its peeling and shearing performance is better, but it has a stronger plastic feel and is not soft enough.

At present, non-woven fabric front waist stickers have been widely used. Compared with the soft velvet type front waist stickers, they have cost advantages, but their peeling and shearing performance and stability are not as good as those of the soft velvet type front waist stickers.

In order to meet the demand for product differentiation in different diaper product designs, Velcro products have also formed different composite product forms, mainly including Y-shaped composite Velcro, S-cut composite Velcro, and Velcro with elastic big ears compound, etc. At present, the degree of automation of diaper production equipment has been greatly improved. More and more manufacturers use the form of online Velcro compounding to design more left and right waist sticker structures.

The tensile and resilience performance of the elastic waistband material will directly affect the comfort of the diaper waist and the risk of back urine leakage. In the early days, the elastic waistband chose foam materials with low cost. This elastic material had poor tensile and resilience performance and is now basically no longer used.

Through the comparison of the tensile stress and strain curves of the elastic film and the foam, it was found that when the foam was used as the elastic waistband, its initial opening force was greater. When the elastic film was used as the elastic waistband, the stress-strain curve was gentle, and the force required to achieve the same tensile rate was smaller, and the user's comfort was higher.

The two tensile and closing curves of the elastic film basically overlap, indicating a high degree of elastic deformation recovery, ensuring that the diaper will not relax or slip. Currently, the significant improvement in the capacity of diaper production equipment has made spandex filament materials widely used as elastic waistband materials. Spandex filament materials have low cost and good tensile performance, and are widely recognized at this stage. Some diaper products, when designing the structure, do not use the elastic waistband at the back, but combine the elastic material with the left and right waist stickers to design a unique diaper product with an elastic big ear structure.

Through continuous research and development and improvement, diaper products are increasingly pursuing the humanized concepts of "softness" and "thinness and lightness". "Softness" and "thinness and lightness" are also the main development directions of the diaper closure system at this stage.

In order to improve the softness of Velcro products, some have specially developed ultra-soft Velcro. This type of Velcro is the thinnest and softest Velcro product currently visible. When paired with the front waist sticker, it has excellent peeling and shearing effects. It is a revolutionary advancement in Velcro product technology and effectively improves the comfort of diaper users.

The emergence of this ultra-thin Velcro is in line with the trends of thinness and softness of diapers. The Velcro on the left and right waist stickers is softer, and consumers have a better feel when using it, effectively preventing damage to the baby's skin.

In order to save the production cost of diapers, the diaper structure without using the front waist sticker has also attracted more and more attention. After many tests and improvements, we found that this product structure can use the new Velcro technology (patterned Velcro), and directly use the compound Velcro with the base film non-woven fabric of the diaper to meet the performance requirements of the diaper. The technological progress of the new Velcro product has made this new design concept of the closure system possible.

Compared with the traditional compound Velcro, the new type of compound Velcro with patterns can maintain a smoother and continuous peeling effect. In terms of performance, it is more suitable for the diaper product structure directly paired with the base film non-woven fabric. When directly paired with the base film non-woven fabric of the diaper, it can fully meet the performance requirements of the diaper. At the same time, this structure of compound Velcro with patterns can not only bring a better aesthetic vision but also significantly enhance the differentiation of diapers.

At present, the domestic pull-up diaper market is growing rapidly, and pull-up diapers mainly use the full elastic waistband of spandex filament. With the breakthrough of elastic film technology, mechanically oriented (MD-oriented) stretchable elastic films have also begun to be used in the design of pull-up diaper products. This new type of pull-up diaper design is closer to the appearance and wearing experience of underwear than traditional pull-up diapers, greatly improving the wearing comfort of pull-up diaper users. At the same time, it greatly improves the privacy of users. For adult diaper users, especially for adults with mild incontinence, using this type of underwear-like diaper can effectively help them reduce their psychological burden.

The development of new material technology has played a key role in improving the performance of diaper products and has contributed to the design of more humanized and ideal diaper products. "Softness" and "thinness and lightness" remain the main development trends of diapers at this stage, and the diaper closure system also needs more innovations for this.

Under the background of increasingly fierce competition in the diaper market, a more perfect closure system has a huge role in promoting the differentiation of diaper brands and consumers' awareness.