Author:Hengdaxin Diaper Material SupplierFROM:Diaper Materials Manufacturer TIME:2024-07-17

Choosing and Innovating with Hook Side Tape

Hook side tape is a fundamental component in various industries, ranging from medical to automotive and beyond. The selection and innovation of hook side tape involve understanding its diverse applications, materials, and manufacturing processes. This article delves into the intricacies of choosing and innovating with hook side tape, exploring its significance, functionalities, and evolving technologies.

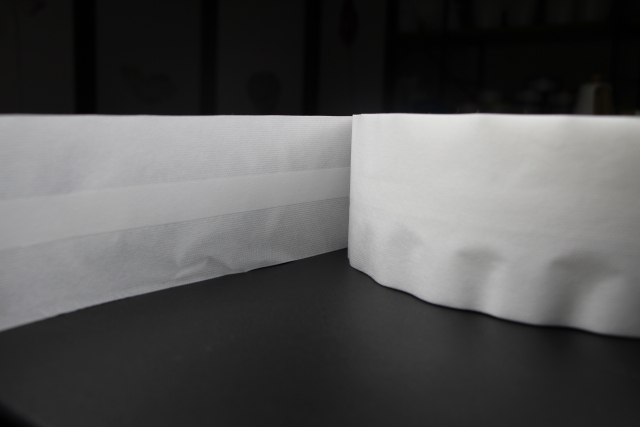

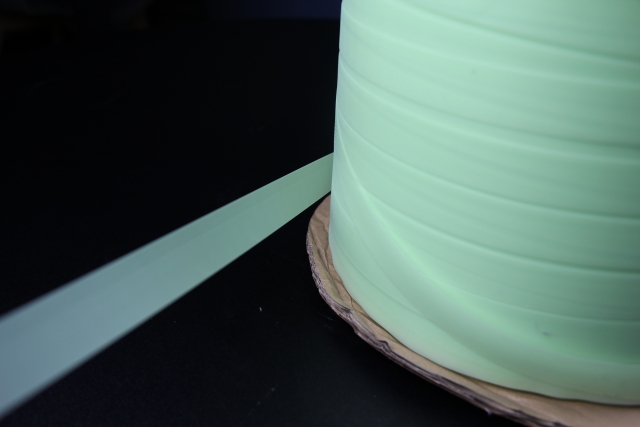

Hook side tape, often part of hook and loop fastening systems, consists of tiny hooks that interlock with loops on loop side tape or other compatible surfaces. Originally inspired by burdock burrs, these tapes provide a versatile alternative to traditional fasteners like zippers and buttons. They are renowned for their reusable, adjustable, and easy-to-use properties, making them indispensable in numerous applications.

Hook side tape finds applications across diverse industries. In the medical field, it secures wound dressings and supports medical devices due to its gentle yet secure closure. In apparel and fashion, it enables quick adjustments and closures in garments. Moreover, in aerospace and automotive sectors, it serves as a lightweight, reliable fastening solution for interior components and upholstery.

When selecting hook side tape, several factors come into play. Strength and durability are crucial for applications requiring frequent use. Compatibility with loop side tape or other surfaces affects the effectiveness of closures. Additionally, considerations such as adhesion strength, washability, and environmental resistance are vital depending on the intended application environment.

The materials used in hook side tape influence its performance characteristics significantly. Nylon and polyester are common choices due to their durability and resilience. Manufacturing techniques, including weaving, knitting, or molding, impact the tape's strength and precision of hook formation. Innovations in manufacturing, such as laser-cutting for precise hook shapes, continue to enhance functionality and customization options.

With increasing focus on sustainability, the hook side tape industry is evolving to meet eco-friendly standards. Biodegradable materials and recycling initiatives are gaining traction to reduce environmental impact. Innovations in adhesive technologies aim to improve recyclability and reduce waste during production and disposal phases.

Advancements in hook side tape technology are driving innovation across industries. Nano-coatings enhance durability and water resistance, expanding applications in outdoor gear and marine environments. Smart textiles integrated with conductive materials enable electronic functionalities, transforming wearable technology and medical monitoring devices.

The future of hook side tape lies in continuous innovation and adaptation to emerging trends. Miniaturization of hooks for finer applications, such as electronics and micro-medical devices, is underway. Integration with nanotechnology offers prospects for self-healing materials and enhanced performance in extreme conditions. Furthermore, customization through digital fabrication techniques like 3D printing holds promise for bespoke solutions in niche markets.

In conclusion, hook side tape remains a cornerstone of modern fastening solutions, indispensable across industries for its versatility and reliability. Choosing the right tape involves considering application-specific requirements and technological advancements. As innovation continues to drive the industry forward, sustainability and customization will shape the future landscape of hook side tape, ensuring it meets evolving global demands.